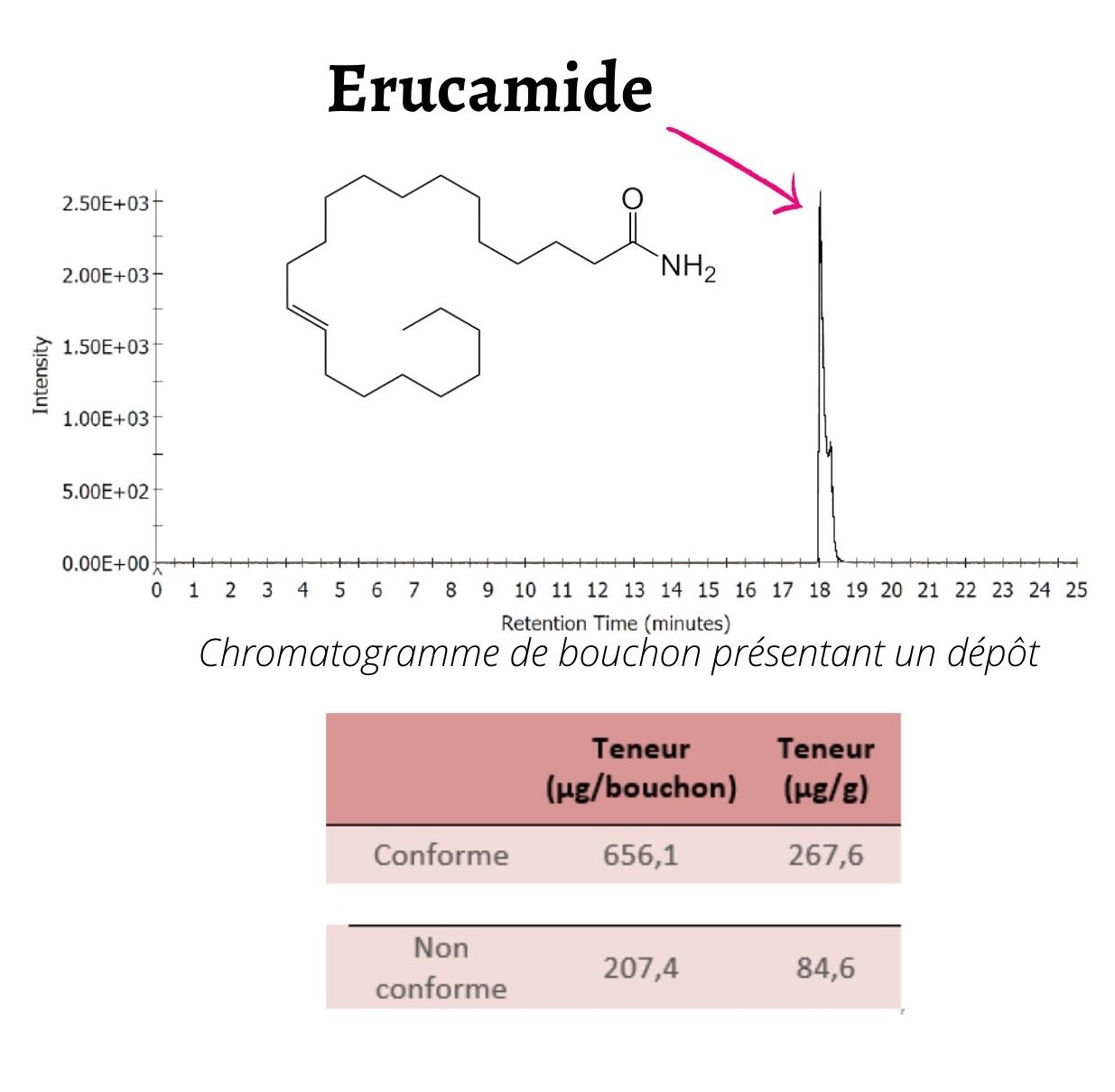

In this case two types of caps were analyzed UPLC / TOF-MS:

- A witness cap with no trace of deposit

- A stopper presenting the deposit

These analyzes revealed a much greater quantity at the surface of Erucamide [112-84-5] stoppers in the non-conforming stopper compared to the conforming stopper.

Our team then made two hypotheses:

1) Erucamide [112-84-5] present in healthy corks would have

migrated from the heart to the surface of the corks following a

thermal shock (increase then sudden decrease in temperature or vice versa)

2) Erucamide [112-84-5] was

overdosed during the manufacture of the batch of non-compliant stoppers, therefore inducing the appearance of this deposit.

EN

EN

FR

FR