Analysis of "Epoxy" type adhesives

Epoxy adhesives offer high mechanical strength, low shrinkage, excellent adhesion to a variety of substrates, good electrical insulation as well as incomparable chemical and thermal resistance. Thus, they are essential in various applications such as paints, adhesives, coating of electronic components as well as composites.

Polymerization is carried out either by polycondensation of the epoxy resin with a nucleophilic hardener (more common) or by homopolymerization of the epoxy resin using an ionic catalyst (less common). These are therefore two-component systems (2k) made up of a base (resin) and a hardener to be mixed in stoichiometric proportions.

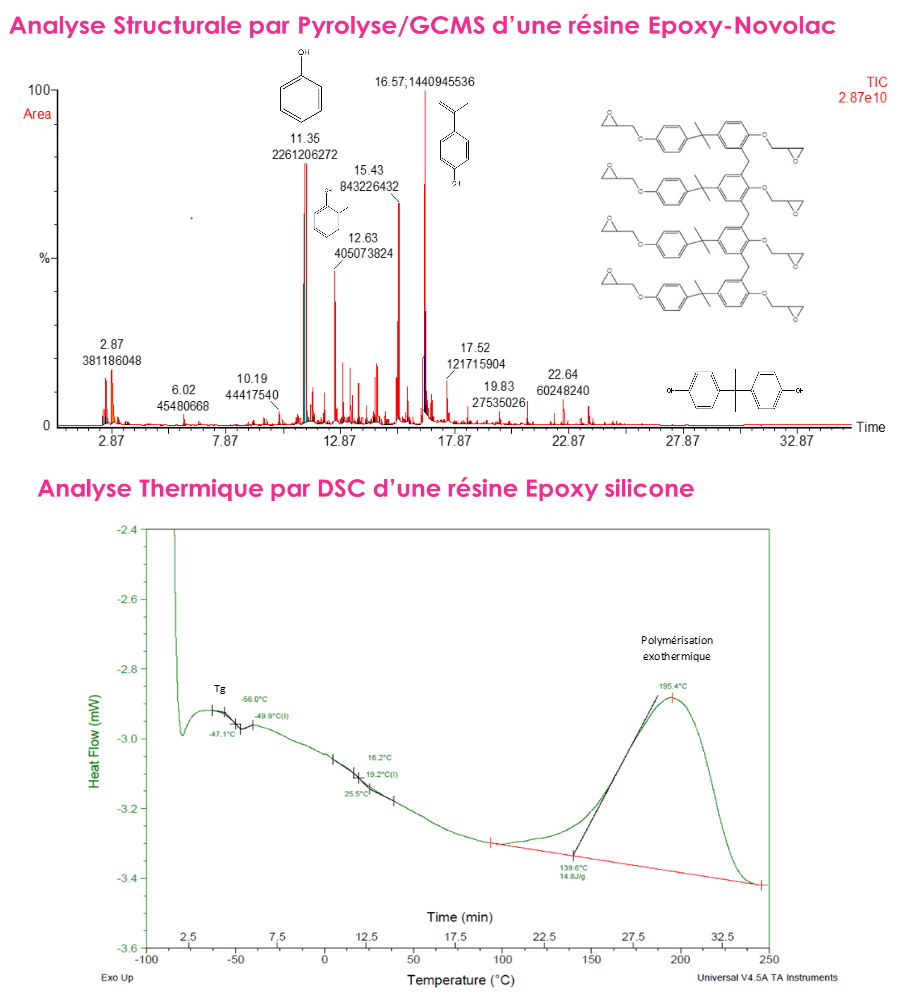

In the vast majority of cases, the base (resin) will consist of a prepolymer resulting from the polyaddition of a polyepoxide (DGEBA, DGEBF, Epoxy-Novolac, BDDE…) on a polyfunctional (polyamine, polyol, polyester…) and the hardener will consist of a mixture of polyfunctionals (polyamine, polyol, polyester, anhydride, etc.) and adjuvants (catalyst, accelerator, etc.).

EN

EN

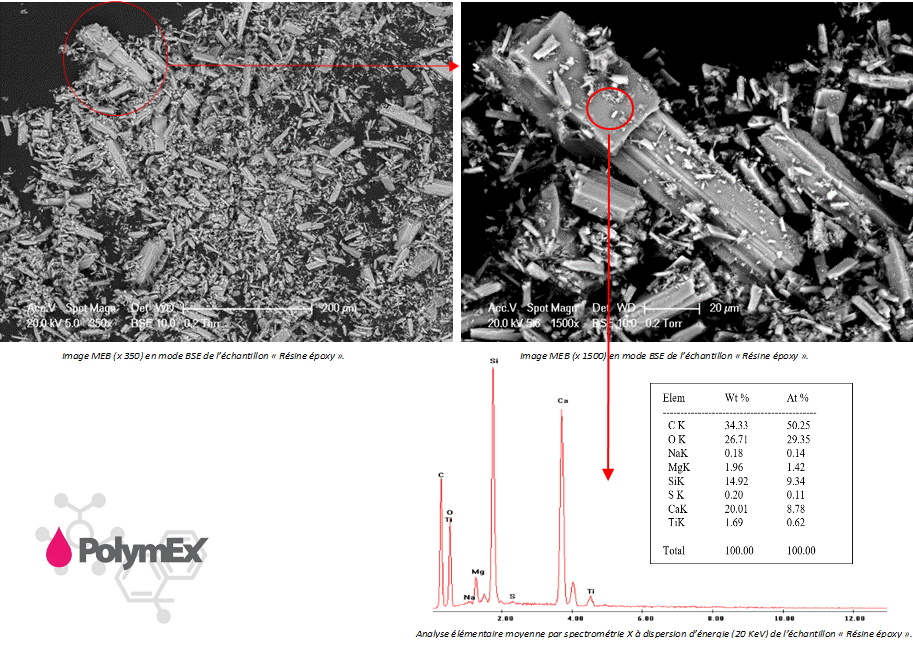

FR

FR